What Is Nano Technology?

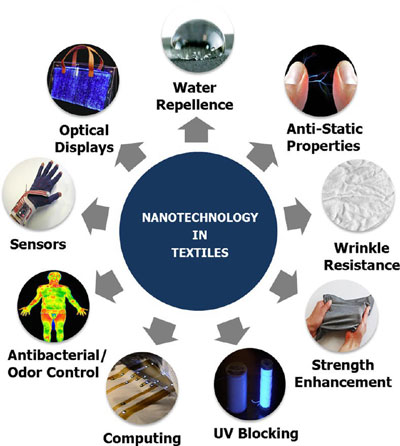

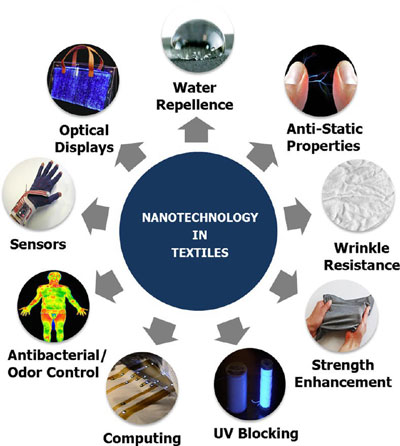

(Nanowerk Spotlight) Nanoengineered functional textiles are going to revolutionize the clothing that you'll wear. The potential of nanotechnology in the development of new materials in the textile industry is considerable. On the one hand, existing functionality can be improved using nanotechnology and on the other, it could make possible the manufacture of textiles with entirely new properties or the combination of different functions in one textile material (read our previous Nanowerk Spotlight on this topic: "Nanotechnology textiles"). Applications of nanotechnology in textiles. (Reprinted with permission by American Chemical Society)A first generation of nano-enhanced textiles benefitted from nano finishing: Coating the surface of textiles and clothing with nanoparticles is an approach to the production of highly active surfaces to have UV-blocking, antimicrobial, antistatic, flame retardant, water and oil repellent, wrinkle resistant, and self-cleaning properties.One stubborn hurdle that prevents nanomaterial-enhanced textiles from becoming more of a commercial reality is the insufficient durability of nanocoatings on textile fibers or the stability of various properties endowed by nanoparticles. Quite simply put, the 'smart' comes off during washing.While antimicrobial properties are exerted by nano-silver, UV blocking, self-cleaning and flame-retardant properties are imparted by nano-metal oxide coatings. Zinc oxide nanoparticles embedded in polymer matrices like soluble starch are a good example of functional nanostructures with potential for applications such as UV-protection ability in textiles and sunscreens, and antibacterial finishes in medical textiles and inner wears (read more about nanofinishing in textile technology).

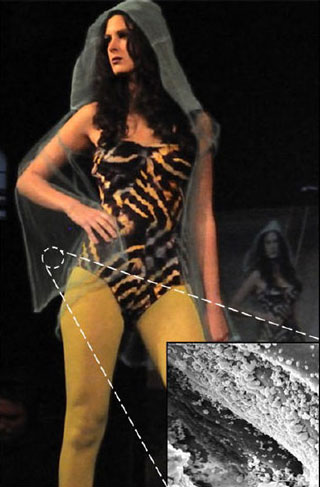

Applications of nanotechnology in textiles. (Reprinted with permission by American Chemical Society)A first generation of nano-enhanced textiles benefitted from nano finishing: Coating the surface of textiles and clothing with nanoparticles is an approach to the production of highly active surfaces to have UV-blocking, antimicrobial, antistatic, flame retardant, water and oil repellent, wrinkle resistant, and self-cleaning properties.One stubborn hurdle that prevents nanomaterial-enhanced textiles from becoming more of a commercial reality is the insufficient durability of nanocoatings on textile fibers or the stability of various properties endowed by nanoparticles. Quite simply put, the 'smart' comes off during washing.While antimicrobial properties are exerted by nano-silver, UV blocking, self-cleaning and flame-retardant properties are imparted by nano-metal oxide coatings. Zinc oxide nanoparticles embedded in polymer matrices like soluble starch are a good example of functional nanostructures with potential for applications such as UV-protection ability in textiles and sunscreens, and antibacterial finishes in medical textiles and inner wears (read more about nanofinishing in textile technology). Sandy Mattei models a design by Matilda Ceesay with a Permethrin-releasing textile net. (Image: Cornell University)A just published review paper in the February 26, 2016 online edition of ACS Nano ("Nanotechnology in Textiles") discusses electronic and photonic nanotechnologies that are integrated with textiles and shows their applications in displays, sensing, and drug release within the context of performance, durability, and connectivity.In these smart clothes the textile structures themselves perform electronic or electric functions. Ideally, the nanoelectronic components will be completely fused with the textile material, resulting in that textile and non-textile components cannot be differentiated and 'foreign particles' can no longer be seen or felt.

Sandy Mattei models a design by Matilda Ceesay with a Permethrin-releasing textile net. (Image: Cornell University)A just published review paper in the February 26, 2016 online edition of ACS Nano ("Nanotechnology in Textiles") discusses electronic and photonic nanotechnologies that are integrated with textiles and shows their applications in displays, sensing, and drug release within the context of performance, durability, and connectivity.In these smart clothes the textile structures themselves perform electronic or electric functions. Ideally, the nanoelectronic components will be completely fused with the textile material, resulting in that textile and non-textile components cannot be differentiated and 'foreign particles' can no longer be seen or felt.

energy-scavenging fabrics that lead to wearable 'smart' clothes that can power integrated electronics and sensors through ordinary body movements;

Interwoven solar cells that turn T-shirts into power textiles;

a wearable textile battery that can be recharged by sunlight;

nanoelectronics at the tip of a gloved finger;

graphene yarns that facilitate energy storage textiles;

graphene-coated 'e-textile' that detect noxious gases.

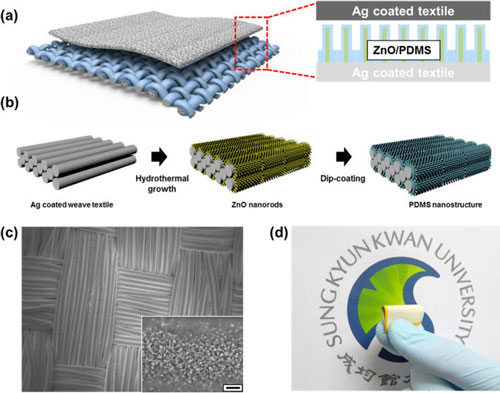

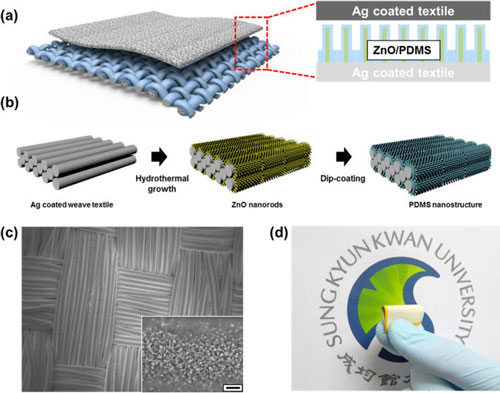

In their review, the authors discuss the electrical conductivity of conducting polymers and graphene, both of which are attractive for creating textiles that enable the incorporation of sensors and actuators.Another section of the review is dedicated to power sources suitable for e-textiles. This covers lightweight fabric carbon nanotube supercapacitor electrodes; stretchable graphene and PPy-based supercapacitors; triboelectric nanogenerators; flexible fiber and stripe batteries; and stretchable PPy-based supercapacitors for energy transfer. (a) Schematic illustration of a wearable triboelectric nanogenerator. (b) Fabrication process of the nanopatterned PDMS structure. (c) FE-SEM images of the bottom textile with nanopatterned PDMS. Inset is a high-resolution image clearly showing the ZnO NR-templated PDMS nanopatterns. (d) Photographic image of the flexible, foldable WTNG. (Reproduced with permission by American Chemical Society) (click on image to enlarge)Adding digital components to these e-textiles would open up an entirely new area of functional clothing. OLEDs in fiber form could lead to revolutionary applications by integrating optical and optoelectronic devices into textile. Combined with nanoelectronic devices, we might one day see flexible optical sensors and display screens woven into shirts and other garments. You could literally wear your next-generation smart phone or iPad on your sleeves; including the solar panels to power them (read more: "Light-emitting nanofibers shine the way for optoelectronic textiles").

(a) Schematic illustration of a wearable triboelectric nanogenerator. (b) Fabrication process of the nanopatterned PDMS structure. (c) FE-SEM images of the bottom textile with nanopatterned PDMS. Inset is a high-resolution image clearly showing the ZnO NR-templated PDMS nanopatterns. (d) Photographic image of the flexible, foldable WTNG. (Reproduced with permission by American Chemical Society) (click on image to enlarge)Adding digital components to these e-textiles would open up an entirely new area of functional clothing. OLEDs in fiber form could lead to revolutionary applications by integrating optical and optoelectronic devices into textile. Combined with nanoelectronic devices, we might one day see flexible optical sensors and display screens woven into shirts and other garments. You could literally wear your next-generation smart phone or iPad on your sleeves; including the solar panels to power them (read more: "Light-emitting nanofibers shine the way for optoelectronic textiles").

Nanotechnology is science, engineering, and technology conducted at the nanoscale, which is about 1 to 100 nanometers.

|

Physicist Richard Feynman, the father of nanotechnology.

|

Nanoscience and nanotechnology are the study and application of extremely small things and can be used across all the other science fields, such as chemistry, biology, physics, materials science, and engineering.

The ideas and concepts behind nanoscience and nanotechnology started with a talk entitled “There’s Plenty of Room at the Bottom” by physicist Richard Feynman at an American Physical Society meeting at the California Institute of Technology (CalTech) on December 29, 1959, long before the term nanotechnology was used. In his talk, Feynman described a process in which scientists would be able to manipulate and control individual atoms and molecules. Over a decade later, in his explorations of ultraprecision machining, Professor Norio Taniguchi coined the term nanotechnology. It wasn't until 1981, with the development of the scanning tunneling microscope that could "see" individual atoms, that modern nanotechnology began.

| ) |

It’s hard to imagine just how small nanotechnology is. One nanometer is a billionth of a meter, or 10-9 of a meter. Here are a few illustrative examples:

- There are 25,400,000 nanometers in an inch

- A sheet of newspaper is about 100,000 nanometers thick

- On a comparative scale, if a marble were a nanometer, then one meter would be the size of the Earth

Nanoscience and nanotechnology involve the ability to see and to control individual atoms and molecules. Everything on Earth is made up of atoms—the food we eat, the clothes we wear, the buildings and houses we live in, and our own bodies.

But something as small as an atom is impossible to see with the naked eye. In fact, it’s impossible to see with the microscopes typically used in a high school science classes. The microscopes needed to see things at the nanoscale were invented relatively recently—about 30 years ago.

Once scientists had the right tools, such as the scanning tunneling microscope (STM) and the atomic force microscope (AFM), the age of nanotechnology was born.

Although modern nanoscience and nanotechnology are quite new, nanoscale materials were used for centuries. Alternate-sized gold and silver particles created colors in the stained glass windows of medieval churches hundreds of years ago. The artists back then just didn’t know that the process they used to create these beautiful works of art actually led to changes in the composition of the materials they were working with.

Today's scientists and engineers are finding a wide variety of ways to deliberately make materials at the nanoscale to take advantage of their enhanced properties such as higher strength, lighter weight, increased control of light spectrum, and greater chemical reactivity than their larger-scale counterparts.

Nanotechnology in textiles - the new black:

Applications of nanotechnology in textiles. (Reprinted with permission by American Chemical Society)A first generation of nano-enhanced textiles benefitted from nano finishing: Coating the surface of textiles and clothing with nanoparticles is an approach to the production of highly active surfaces to have UV-blocking, antimicrobial, antistatic, flame retardant, water and oil repellent, wrinkle resistant, and self-cleaning properties.One stubborn hurdle that prevents nanomaterial-enhanced textiles from becoming more of a commercial reality is the insufficient durability of nanocoatings on textile fibers or the stability of various properties endowed by nanoparticles. Quite simply put, the 'smart' comes off during washing.While antimicrobial properties are exerted by nano-silver, UV blocking, self-cleaning and flame-retardant properties are imparted by nano-metal oxide coatings. Zinc oxide nanoparticles embedded in polymer matrices like soluble starch are a good example of functional nanostructures with potential for applications such as UV-protection ability in textiles and sunscreens, and antibacterial finishes in medical textiles and inner wears (read more about nanofinishing in textile technology).

Applications of nanotechnology in textiles. (Reprinted with permission by American Chemical Society)A first generation of nano-enhanced textiles benefitted from nano finishing: Coating the surface of textiles and clothing with nanoparticles is an approach to the production of highly active surfaces to have UV-blocking, antimicrobial, antistatic, flame retardant, water and oil repellent, wrinkle resistant, and self-cleaning properties.One stubborn hurdle that prevents nanomaterial-enhanced textiles from becoming more of a commercial reality is the insufficient durability of nanocoatings on textile fibers or the stability of various properties endowed by nanoparticles. Quite simply put, the 'smart' comes off during washing.While antimicrobial properties are exerted by nano-silver, UV blocking, self-cleaning and flame-retardant properties are imparted by nano-metal oxide coatings. Zinc oxide nanoparticles embedded in polymer matrices like soluble starch are a good example of functional nanostructures with potential for applications such as UV-protection ability in textiles and sunscreens, and antibacterial finishes in medical textiles and inner wears (read more about nanofinishing in textile technology). Sandy Mattei models a design by Matilda Ceesay with a Permethrin-releasing textile net. (Image: Cornell University)A just published review paper in the February 26, 2016 online edition of ACS Nano ("Nanotechnology in Textiles") discusses electronic and photonic nanotechnologies that are integrated with textiles and shows their applications in displays, sensing, and drug release within the context of performance, durability, and connectivity.In these smart clothes the textile structures themselves perform electronic or electric functions. Ideally, the nanoelectronic components will be completely fused with the textile material, resulting in that textile and non-textile components cannot be differentiated and 'foreign particles' can no longer be seen or felt.

Sandy Mattei models a design by Matilda Ceesay with a Permethrin-releasing textile net. (Image: Cornell University)A just published review paper in the February 26, 2016 online edition of ACS Nano ("Nanotechnology in Textiles") discusses electronic and photonic nanotechnologies that are integrated with textiles and shows their applications in displays, sensing, and drug release within the context of performance, durability, and connectivity.In these smart clothes the textile structures themselves perform electronic or electric functions. Ideally, the nanoelectronic components will be completely fused with the textile material, resulting in that textile and non-textile components cannot be differentiated and 'foreign particles' can no longer be seen or felt.Electronics in textiles

We have written extensively about smart textiles, for instance (a) Schematic illustration of a wearable triboelectric nanogenerator. (b) Fabrication process of the nanopatterned PDMS structure. (c) FE-SEM images of the bottom textile with nanopatterned PDMS. Inset is a high-resolution image clearly showing the ZnO NR-templated PDMS nanopatterns. (d) Photographic image of the flexible, foldable WTNG. (Reproduced with permission by American Chemical Society) (click on image to enlarge)Adding digital components to these e-textiles would open up an entirely new area of functional clothing. OLEDs in fiber form could lead to revolutionary applications by integrating optical and optoelectronic devices into textile. Combined with nanoelectronic devices, we might one day see flexible optical sensors and display screens woven into shirts and other garments. You could literally wear your next-generation smart phone or iPad on your sleeves; including the solar panels to power them (read more: "Light-emitting nanofibers shine the way for optoelectronic textiles").

(a) Schematic illustration of a wearable triboelectric nanogenerator. (b) Fabrication process of the nanopatterned PDMS structure. (c) FE-SEM images of the bottom textile with nanopatterned PDMS. Inset is a high-resolution image clearly showing the ZnO NR-templated PDMS nanopatterns. (d) Photographic image of the flexible, foldable WTNG. (Reproduced with permission by American Chemical Society) (click on image to enlarge)Adding digital components to these e-textiles would open up an entirely new area of functional clothing. OLEDs in fiber form could lead to revolutionary applications by integrating optical and optoelectronic devices into textile. Combined with nanoelectronic devices, we might one day see flexible optical sensors and display screens woven into shirts and other garments. You could literally wear your next-generation smart phone or iPad on your sleeves; including the solar panels to power them (read more: "Light-emitting nanofibers shine the way for optoelectronic textiles").

Nice work done bro

ReplyDeleteThanks bro

ReplyDelete